Introduction:

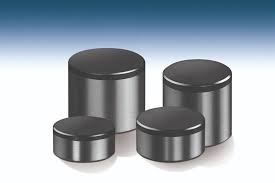

PDC (polycrystalline diamond compact) cutters are an essential component in mining drilling operations. These cutters are designed to provide high-performance cutting and drilling capabilities, making them critical for achieving mining targets. Proper maintenance and repair of PDC cutters can help maximize their lifespan and performance, reducing downtime and increasing productivity. Huanghe Whirlwind, a leading manufacturer of PDC cutters, shares some tips for maintaining and repairing PDC cutters to optimize their performance in mining applications.

Inspecting PDC Cutters:

Regular inspection of PDC cutters is crucial to ensure they are functioning optimally. Inspections should include checking for any signs of wear, damage, or cracking. If any of these issues are detected, the cutter should be repaired or replaced immediately. It is also essential to check the condition of the PDC cutters' mounting hardware, including the bolts and clamps.

Cleaning PDC Cutters:

Proper cleaning of PDC cutters is essential to maximize their lifespan and performance. Dirt, dust, and debris can accumulate on the cutter's surface, reducing its cutting efficiency. Cleaning should be done using a soft-bristled brush and a mild cleaning solution. It is important to avoid using harsh chemicals or abrasives, which can damage the cutter's surface.

Repairing PDC Cutters:

When a PDC cutter is damaged or worn, it should be repaired immediately to prevent further damage or failure. Huanghe Whirlwind recommends using a professional PDC cutter repair service, as they have the expertise and tools to repair the cutter correctly. Repair techniques may include polishing the cutter's surface, reapplying diamond coatings, or replacing worn or damaged components.

Replacing PDC Cutters:

When a PDC cutter is beyond repair, it should be replaced. It is essential to use a high-quality replacement cutter from a reputable manufacturer like Huanghe Whirlwind. The replacement cutter should be the same size and type as the damaged or worn cutter to ensure optimal performance.