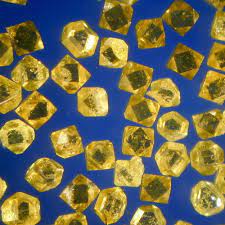

Synthetic diamonds, also known as cultivated diamonds, are produced by simulating the natural diamond crystallization process. There is no significant difference between cultivated diamonds and natural diamonds in terms of crystal structure integrity, transparency, refractive index, and dispersion. Against the backdrop of shrinking natural diamond mining resources, in 2018, the FTC (U.S. Federal Trade Commission) included cultivated diamonds in the diamond category. Cultivated diamonds have opened the era of replacing natural diamonds.

Globally, China leads in the production of synthetic diamonds, and within China, Henan province is the leader. Driven by the synthetic diamond industry cluster, China has become the world's largest synthetic diamond production base. With exquisite technology and craftsmanship, Henan's synthetic diamonds have achieved great success worldwide. In Henan province, the production capacity of Zhongnan Diamond, Huanghe Whirlwind, and Yuguang Diamond accounts for more than 80% of the domestic market, and these three companies are also the main producers of gem-quality large single crystals. In the high-grade carat diamond field, Huanghe Whirlwind currently holds a market share of over 50%, occupying an absolute leading position.

In recent years, Huanghe Whirlwind has been committed to transforming "Made in China" into "Intelligently Made in China" by expanding production capacity, technological innovation, and standardized management to continuously improve the yield of cultivated diamond products. The company has partnered with China Unicom to build the first "5G+ Smart Factory" project in the national superhard materials industry. Huanghe Whirlwind will take the opportunity of the "5G+ Smart Factory" project construction to gradually realize the informationization of industrial equipment and digitalization of production processes throughout the company, making Huanghe Whirlwind a benchmark enterprise for intelligent manufacturing.

It is reported that the Huanghe Whirlwind 5G+ Smart Factory project is divided into two phases. The first phase will build an industrial internet platform, including big data acquisition and monitoring systems, big data analysis, machine learning algorithm models, etc., all embedded in the 5G intelligent network to form a 5G+ artificial intelligence production model. This can achieve intelligent monitoring of existing diamond press machines and intelligent collection and analysis of environmental data, and is expected to increase the yield of high-grade diamonds to over 80%, significantly better than the average level of artificial synthesis. The second phase will integrate ERP, MES, big data + AI intelligent analysis, 5G+ MEC+ UPF hybrid cloud mode, etc., to provide customers with personalized customization, inspection, and testing services, accelerating the company's transformation from a single product manufacturer to a system service provider.