Introduction:

Drilling is a critical part of coal mining operations, but it's not without its challenges. The drill bit, in particular, is a critical component that plays a vital role in the success of any drilling operation. In this article, we'll explore some of the key challenges that drill bits face when drilling in coal mining operations and how companies like Huanghe Whirlwind are working to overcome them.

The Challenges of Drill Bits in Coal Mining:

Extreme Heat and Pressure:

Drilling in coal mining operations requires drill bits to operate under extreme heat and pressure. As the drill bit cuts through rock and coal, friction generates heat, which can cause the bit to wear down and even break.

Abrasive Materials

Coal mining operations often involve drilling through abrasive materials, such as sandstone, shale, and limestone. These materials can cause significant wear and tear on drill bits, reducing their effectiveness and lifespan.

Impact and Vibration

The impact and vibration caused by drilling can also take a toll on drill bits, causing them to break or wear down more quickly.

How Huanghe Whirlwind is Addressing These Challenges:

Huanghe Whirlwind is a leading manufacturer of drill bits for the coal mining industry. To address the challenges of drilling in this environment, the company has developed a range of innovative solutions, including:

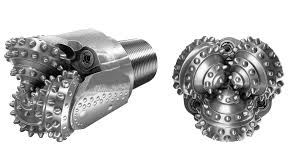

PDC Drill Bits

Huanghe Whirlwind's PDC (polycrystalline diamond compact) drill bits are designed to operate under extreme heat and pressure. The diamond compact material is highly resistant to wear and can withstand the harsh conditions of coal mining operations.

Tungsten Carbide Inserts

Huanghe Whirlwind's tungsten carbide inserts provide added durability and wear resistance. These inserts are made from a high-strength material that can withstand the abrasive materials commonly found in coal mining.

Advanced Manufacturing Techniques

Huanghe Whirlwind uses advanced manufacturing techniques, such as hot isostatic pressing (HIP) and sintering, to produce drill bits that are highly resistant to impact and vibration.

Conclusion:

Drill bits are a critical component of coal mining operations, but they face significant challenges when operating in this environment. Companies like Huanghe Whirlwind are working to overcome these challenges by developing innovative solutions that can withstand the extreme heat, pressure, and abrasion of coal mining. With the use of PDC drill bits, tungsten carbide inserts, and advanced manufacturing techniques, Huanghe Whirlwind is leading the way in the development of drill bits that can withstand the toughest conditions of coal mining operations.

Subheading: The Importance of High-Quality Drill Bits in Coal Mining

High-quality drill bits are essential for the success of any coal mining operation. Learn why investing in the best drill bits is critical to maximizing productivity, minimizing downtime, and ensuring worker safety.